Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

Wheel Cylinder Inspection & Service

Wheel cylinders are not exactly high-tech components, but they do play a vital role in drum brakes. When the driver steps on the brake pedal, hydraulic pressure from the master cylinder pushes the two pistons inside each wheel cylinder outward to force the brake shoes against the drums and apply the brakes. When the brake pedal is released, return springs pull the shoes back away from the drums and push the wheel cylinder pistons back into their bores.

As long as the wheel cylinders are working correctly and are not leaking, the brakes should apply and release just fine. But, if a wheel cylinder is sticking or leaking, it can cause the brakes to grab or pull.

A leaky wheel cylinder is dangerous because it may allow a complete loss of hydraulic pressure in the affected brake circuit. This, in turn, can cause the brakes to fail. Consequently, repairs should be made immediately if a wheel cylinder is leaking fluid.

INSIDE BRAKE WHEEL CYLINDER

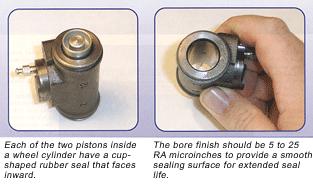

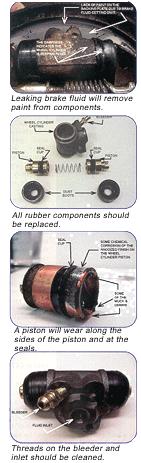

Each of the two pistons inside a wheel cylinder have a cup-shaped rubber seal that faces inward. The seal is job is to hold pressure and prevent brake fluid from leaking past the piston. On the outside of each piston is a rubber dust boot that fits around the end of the wheel cylinder to keep moisture, dirt and brake dust out of the cylinder bore.

Over time, normal wear may cause the piston seals to leak. Corrosion and pitting can also occur inside wheel cylinders as moisture builds up in the brake fluid and the corrosion inhibitors in the fluid break down. This tends to be more of a problem in wet environments with high humidity. After five or six years of service, the bores may become rough and cause the seals to fail.

When a wheel cylinder fails, it is bad news for the brakes. Fluid that seeps past the piston seals usually ends up dripping on on he brake linings. Fluid contaminated linings can cause uneven braking and grabbing. In such cases, the linings on both sides of the axle should be replaced to restore even braking.

If there is a serious loss of fluid past a leaky wheel cylinder seal, the driver may experience a loss of pedal and possible brake failure.

Sticking is another problem that may afflict a wheel cylinder. Sometimes a piston will stick in its bore because dirt or corrosion acts like a wedge and jams it tight. If this happens, the brake may not release causing the shoe to drag.

WHEEL CYLINDER INSPECTION

Because of their hidden location inside the brake drums, wheel cylinders cannot be visually inspected unless the drums are removed, and that only happens when the brake shoes are being replaced or a wheel cylinder is obviously leaking.

The rear brake linings on most vehicles typically last twice as long as the linings up front because the front brakes do most of the work.

With front-wheel drive, the front disc brakes handle up to 80 percent of the braking load. Consequently, the rear linings wear at a much slower rate and are usually ignored until the second or even third brake job.

By the time the rear drums are pulled to inspect and redo the rear linings, the vehicle may have racked up 60,000, 80,000 or even 100,000 miles. That is a lot of miles on the original piston seals and dust boots.

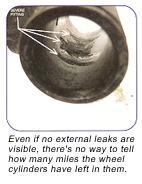

Wear and corrosion inside the wheel cylinders may be reaching a critical point, even if no external leaks are yet visible. There is no way to tell how many miles the wheel cylinders have left in them, so many experts recommend replacing the wheel cylinders when doing a brake job on a high mileage vehicle.

Remember, it will probably be a long time (if ever) before the rear drums are pulled again, so you may only have one shot at replacing the wheel cylinders on the vehicle.

Some consumers may see this as "unnecessary" repair work, yet they would be the first ones to complain if a wheel cylinder started to leak a few thousand miles after their vehicle had new brake linings installed.

It is a fact that wheel cylinders eventually wear out, and when they do they can cause serious braking problems or even brake failure. Why take unnecessary chances on a high mileage vehicle when all you have to do is replace the wheel cylinders to restore the brakes to like-new condition?

Wheel cylinders are not expensive and add little to the overall cost of a complete brake job. They are relatively easy to replace in most cases, and do not require much extra labor if you are already pulling the drums to inspect and replace the rear linings.

RISKS OF REUSING OLD CYLINDERS

When new brake shoes are installed, the wheel cylinder pistons must be pushed further back in their bores to accommodate the thicker shoes. This causes the seals to ride on an area of the bore that has probably become rough due to internal corrosion and pitting, which can lead to seal failure within a few hundred or few thousand miles.

It is the same situation with disc brake calipers. Piston seals can also become brittle and hard as they age. So replacing the wheel cylinders (and calipers) when the brakes are relined reduces the risk of problems and maximizes the life of the brake system.

REBUILD OR REPLACE?

The days of rebuilding wheel cylinders is pretty much over as far as professional technicians are concerned. Rebuilding is still a repair option, but takes time and increases the risk of a comeback if you do not do it properly.

If a wheel cylinder is worn or pitted excessively, light honing is not going to restore it. Besides, a honed cylinder will still have more clearance than a new cylinder. The recommended piston-to-bore clearance in many wheel cylinders is about .006 of an inch. More than that increases the risk of seal leakage and piston rocking that will increase wear even more as well as the possibility of the piston sticking.

Aluminum wheel cylinders should not be honed because doing so removes the anodized coating that is there to prevent corrosion. Therefore, if you find a worn or leaking aluminum wheel cylinder, it must be replaced.

Many wheel cylinders can be honed in place, but some do not have enough clearance or have internal baffles that prevent a hone from making a clean pass through the housing. Either way, the wheel cylinder must be removed so why not just replace it with a new one?

Replacement may also be necessary if the bleeder screw is frozen or broken off.

NEW WHEEL CYLINDERS

Wheel cylinders are available from a wide variety of sources, and in various levels of quality. The difference in price between a "premium" replacement part and a standard part is not that much, and the premium part is typically made of a higher grade of metal, has a smoother bore finish and uses better seal materials.

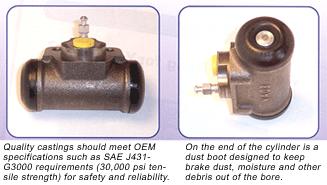

Quality castings should meet OEM specifications such as SAE J431-G3000 requirements (30, 000 psi tensile strength) for safety and reliability. The bore finish should be 5 to 25 RA microinches to provide a smooth sealing surface for extended seal life. You should also look for premium quality SBR rubber cups and EPDM boots for added durability and longevity.

Bleeder screws should be plated to resist corrosion. Some manufacturers also pretest their wheel cylinders at the factory to make sure they seal properly and do not leak.

A good way to judge the quality of the product is the length of its warranty (lifetime is best) and the reputation of the supplier.

Many experts also recommend using replacement wheel cylinders that are made of the same material (cast iron or aluminum) as the original equipment part.

WHEEL CYLINDER INSTALLATION TIPS

On GM vehicles that have the clip-in style wheel cylinders, check for looseness that might allow the wheel cylinder to twist on the backing plate. Various types of repairs are available including new backing plates and reinforcing brackets.

Before you install a new wheel cylinder, clean the mounting surface on the brake backing plate so the cylinder will mount flush against the surface. If the backing plate is badly rusted, bent or otherwise damaged, replace it.

When replacing wheel cylinders, the rubber brake hose and brake hardware (springs, clips, etc.) should also be replaced at the same time to restore the brakes to like-new condition.

Finally, after the new wheel cylinders have been installed they must be bled to remove air that can cause a soft pedal and increase pedal travel.

Adapted from an article written by Larry Carley for Brake & Front End magazine

Back to Brake | Back to Info Main Page

Total messages: 0