Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

Brake Master Cylinder

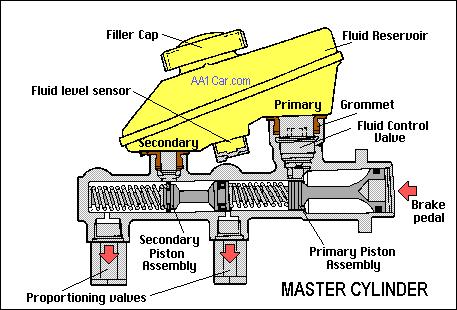

The master cylinder is the heart of the brake's hydraulic system. It converts the force exerted on the brake pedal into hydraulic pressure to apply the brakes. Depressing the brake pedal moves a push rod in the master cylinder. Mounted on the push rod are a pair of pistons (primary and secondary) in tandem (one after the other) that exert force against the fluid in the master cylinder bore. The pressure created displaces fluid through the various brake circuits and lines to each of the wheels and applies the brakes.

The master cylinder is able to do its job because brake fluid is incompressible. The fluid inside acts like a liquid linkage between the master cylinder's pistons and the calipers and wheel cylinders. Any movement of the pistons in the master cylinder is transferred to each of the brakes. For it to work properly, though, there must be no air in the fluid because air is compressible. That means no bubbles or air pockets in the brake lines, master cylinder, the calipers or the wheel cylinders. And if the vehicle has antilock brakes, no air in the hydraulic modulator assembly or ABS solenoids.

When the brake pedal is released, the spring-loaded piston assembly in the master cylinder returns to its rest position. The fluid that was displaced by the pistons is pushed back to the master cylinder as the disc brake pads and drum brake shoes retract, and the fluid returns to the fluid reservoir through the compensating ports.

On many late model vehicles, a special "quick take-up" master cylinder is used to reduce brake drag for improved fuel economy. The caliper piston seals retract the pistons when the brakes are released so the pads don't drag against the rotors. Because the caliper pistons have to travel further when applied, the master cylinder has a stepped bore that delivers a larger volume of fluid when the brake pedal is initially depressed. These type of master cylinders have a special "quick take-up" valve inside to control the movement of this extra fluid.

MASTER CYLINDER WEAR

Like any other component that receives a lot of use, the master cylinder eventually wears out. Stop-and-go city driving is obviously a lot harder on a master cylinder than highway driving, so a master cylinder that goes 150,000 or more miles in one application may only last 70,000 miles in another.

Master cylinder problems include external leaks, internal leaks and valve problems. Brake fluid leaking from the rear of the master cylinder bore is usually bad news because it means the seals are leaking. But sometimes a leak at the vacuum booster input seal and/or pushrod misalignment can cause a fluid leak, so a closer inspection is needed to determine the cause.

When the master cylinder's pistons and/or bore become worn, the pistons won't hold pressure and the brake pedal will gradually sink when the brakes are applied. Be careful not to confuse this condition with air in the lines that can cause a soft or spongy pedal. A low pedal is usually due to worn linings. If the master cylinder is worn, however, then replacement is recommended.

MASTER CYLINDER: REPAIR OR REPLACE?

Most brake technicians today won't waste their time overhauling a master cylinder with a kit because in many instances the bore is too badly worn. And if the master cylinder is aluminum, it can't be honed because doing so would remove the anodized coating (or what's left of it) that protects the metal against corrosion. So to reduce the liability involved and the risk of a comeback, most technicians simply replace your old master cylinder if it is worn or leaking with a new or remanufactured master cylinder (NOTE: remanufactured aluminum master cylinders are usually sleeved).

The master cylinder may also experience problems if rust or dirt plugs up the compensating or metering ports. This can sometimes create residual pressure in the system causing one or more brakes to drag. If a caliper or wheel cylinder that's in good working condition appears to be dragging, then check out this possibility. Sometimes residual pressure can be created by a misadjusted brake pedal stop light switch.

There is no need to replace the master cylinder if all that is wrong is a bad proportioning or metering valve. The proportioning valve splits the hydraulic pressure so that the front and rear wheels receive just the right amount of pressure when the brakes are applied to compensate for the difference in braking effort and weight distribution front-to-rear. A defective proportioning valve can upset brake balance allowing too much pressure to reach one set of wheels.

When a brake imbalance problem such as rear wheel skidding leads you to suspect something's wrong with the proportioning valve, the valve should be tested or replaced. Testing requires two hydraulic pressure gauges that read up to 2000 PSI. Install one gauge immediately behind the valve and the other ahead of the valve. When pedal pressure is applied, the first gauge will show the output pressure from the master cylinder and the second will read the reduced pressure. If the valve doesn't reduce pressure according to the specs for the vehicle, replace the valve.

When replacing a master cylinder, it's a good idea to bench bleed it before it is installed. This is especially important on tilted master cylinders that trap air in the front chamber (an alternative technique is to raise the rear of your vehicle up with a jack so as to tilt the master cylinder forward until it is level enough to bleed it).

Back to Brake | Back to Info Main Page

Total messages: 0