Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

Crankshaft & Camshaft Position Sensors

Distributorless ignition systems require a crankshaft position sensor (CKP), and sometimes also a camshaft position sensor (CMP). These sensors serve essentially the same purpose as the ignition pickup and trigger wheel in an electronic distributor, the only difference being that the basic timing signal is read off the crankshaft or harmonic balancer instead of the distributor shaft. This eliminates ignition timing variations that can result from wear and backlash in the timing chain and distributor gear. It also does away timing adjustments (or misadjustments as the case may be).

On 1996 vehicles with Onboard Diagnostics II (OBD II), the crankshaft position sensor is also used to detect variations in crank speed caused by ignition misfire. If the computer senses enough of these, it will illuminate or flash the Check Engine or Service Engine Soon light to signal the driver he has a problem.

DIFFERENT TYPES OF CRANKSHAFT POSITION SENSORS

There are a variety of different types of crankshaft position sensors. One is a Hall effect crank position sensor that reads a notched metal "interrupter" ring on the back of the harmonic balancer. This was first used on the early GM 3.8L V6 Buick Sequential Fuel Injection (SFI) engines (and turbos) with distributorless Computer Controlled Coil Ignition (C3I). The crank position sensor provides an on-off signal to the Powertrain Control Module (PCM) that the computer uses to monitor engine rpm and crank position. The system also uses a separate cam position sensor in place of the original distributor to inform the PCM about valve timing. This enables the PCM to determine the correct firing sequence which it then uses to control both injector and ignition timing. Ford uses a similar setup on its 5.0L V8 with distributorless ignition.

Another type of crankshaft position sensor GM uses is the "combination sensor" which you'll find mounted on the front of the 3. 0L and 3300 V6. GM calls it a combination sensor because the crank position sensor contains a pair of hall effect switches that generate two separate signals. There are two notched interrupter rings on the back of the harmonic balancer. One ring has three notches which causes one of the hall effect switches to generate three crank position signals every revolution. The other ring has only one notch, which causes the other hall effect switch to generate a single "sync-pulse" signal that the ECM uses to calculate rpm and ignition timing.

Another variation of the combination sensor is the "fast start" system used on GM's 3800 engine. A pair of Hall effect switches are mounted by the crank pulley while a cam sensor is mounted over the timing gear. One crank signal generates 3 pulses per revolution while the other generates 18. This allows the coil module to "sync" with the engine more quickly so the engine will start almost instantly.

The third type of crankshaft position sensor is a magnetic pickup that reads slots machined in a "reluctor" ring in the center of the crankshaft, on the harmonic balancer or flywheel. This setup is used on GM engines with the Direct Ignition Systems (DIS) on the 2.0L, 2.5L and 2.8L engines, and the Integrated Distributorless Ignition (IDI) on the 2.3L Quad 4, and also many Ford, Chrysler and import engines.

On the GM applications, the crank reluctor ring has six equally spaced slots 60 degrees apart. A seventh slot is spaced 10 degrees from one of the others so the crank sensor will generate an extra "sync-pulse" every revolution. The PCM then uses the information to calculate proper ignition and injector timing. This type of sensor must be carefully positioned so the air gap is within .050 in. of the crankshaft reluctor ring.

CKP & CMP SENSOR DIAGNOSIS

The fastest way to check the crank and/or camshaft sensors on a 1995 or newer vehicle with OBD II is to plug in your scan tool and check for any fault codes.

P0335....Crankshaft Position Sensor A Circuit

P0336....Crankshaft Position Sensor A Circuit Range/Performance

P0337....Crankshaft Position Sensor A Circuit Low Input

P0338....Crankshaft Position Sensor A Circuit High Input

P0339....Crankshaft Position Sensor A Circuit Intermittent

P0340....Camshaft Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

P0341 Camshaft Position Sensor 'A' Circuit Range/Performance (Bank 1)

P0342....Camshaft Position Sensor 'A' Circuit Low Input (Bank 1)

P0343....Camshaft Position Sensor 'A' Circuit High Input (Bank 1)

P0344....Camshaft Position Sensor 'A' Circuit Intermittent (Bank 1)

P0345....Camshaft Position Sensor 'A' Circuit (Bank 2)

P0346....Camshaft Position Sensor 'A' Circuit Range/Performance (Bank 2)

P0347....Camshaft Position Sensor 'A' Circuit Low Input (Bank 2)

P0348....Camshaft Position Sensor 'A' Circuit High Input (Bank 2)

P0349....Camshaft Position Sensor 'A' Circuit Intermittent (Bank 2)

You can also use your scan tool to check for the presence of a cranking rpm signal if an engine is cranking but is not starting because there is no spark (which is often a clue that the crankshaft position sensor is not working).

On pre-OBD II vehicles, you can use a scan tool to check for codes, or use a manual flash code procedure to read out codes. On a pre-OBD II GM application, a trouble Code 12 while cranking would indicate no reference signal being generated. On pre-OBD II Ford applications, a Code 14 would indicate a problem with the crank position sensor signal, which Ford calls a "PIP" (Profile Ignition Pick-up) signal.

CRANK POSITION SENSOR CHECKS

Whether a crankshaft position sensor is the magnetic type or a hall effect switch, most problems can be traced to faults in the wiring harness. A disruption of the sensor supply voltage, ground or return circuits can cause a loss of the all-important timing signal resulting in an engine that cranks but won't start.

Also, on some vehicles, damage to the notched sensor ring on the crankshaft, harmonic balancer or flywheel can cause an erratic crankshaft sensor signal.

When troubleshooting a suspected crankshaft position sensor problem, you should follow the diagnostic flow charts in the vehicle manufacturer12s service literature to isolate the faulty component when a fault code is present, otherwise there is no way to know if a no-spark starting problem is a bad ignition module, coil, computer, wiring fault or ignition switch.

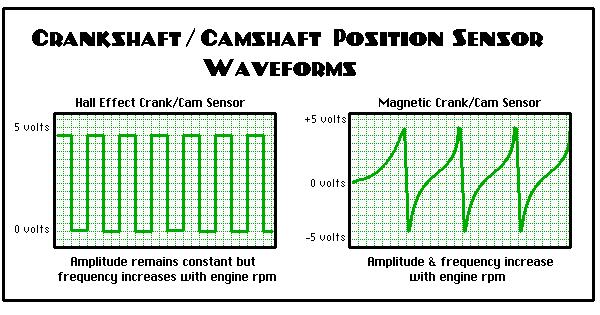

Magnetic sensors can be checked by unplugging the electrical connector and checking resistance between the appropriate terminals. On a GM 2.3L Quad 4, for example, the sensor should read between 500 and 900 ohms. Always refer to the vehicle manufacturers test specifications when testing these sensors. Obviously, if you see a zero resistance reading (shorted) or an infinite (open) reading, the sensor has failed and needs to be replaced. If viewed on an oscilloscope, a magnetic crank sensor will produce a waveform similar to that below:

A good magnetic crank position sensor should produce an alternating current when the engine is cranked, so a voltage output check while cranking is another test that can be performed. With the sensor connected, read the output voltage across the appropriate terminals while cranking the engine. If you see at least 20 mV on the AC scale, the sensor is good, meaning the fault is probably in the module, coil, wiring or computer.

Hall effect crankshaft position sensors typically have three terminals; one for current feed, one for ground and one for the output signal. The sensor must have voltage and ground to produce a signal, so check these terminals first with an analog voltmeter. Sensor output can be checked by disconnecting the coil and cranking the engine to see if the sensor produces a voltage signal. The voltmeter needle should jump each time a shutter blade passes through the Hall effect switch. If observed on an oscilloscope, you should see a square wave form (see above) that changes in frequency.

If your diagnosis reveals a faulty crank sensor, the only option is to replace it. With Hall effect sensors, the sensor must be properly aligned with the interrupter ring to generate a clean signal. Any rubbing or interference could cause idle problems as well as sensor damage. Magnetic crankshaft position sensors must be installed with the proper air gap, which is usually within .050 in. of the reluctor wheel on the crankshaft.

CAMSHAFT POSITION SENSORS

On many engines with distributorless ignition systems and sequential fuel injection, a camshaft position sensor is used to keep the engine's control module informed about the relative position of the crankshaft. By monitoring cam position (which allows the control module to determine when the intake and exhaust valves are opening and closing), the control module can use the cam position sensor's input along with that from the crankshaft position sensor to determine which cylinder in the engine's firing sequence is approaching top dead center. This information is then used by the engine control module to synchronize the pulsing of sequential fuel injectors so they match the firing order of the engine. On some applications, input from the camshaft position sensor is also required for ignition timing.

The camshaft position sensor may be magnetic or Hall effect, and mounted on the timing cover over the camshaft gear, on the end of the cylinder head in an overhead cam application, or in a special housing that replaces the distributor (in the case of some of the GM applications). Operation and diagnosis is essentially the same as that for a crankshaft position sensor.

Back to Driveability Diagnostics Emissions | Back to Info Main Page

Total messages: 0