Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

Electronic Transmissions: TCMs & PCMs

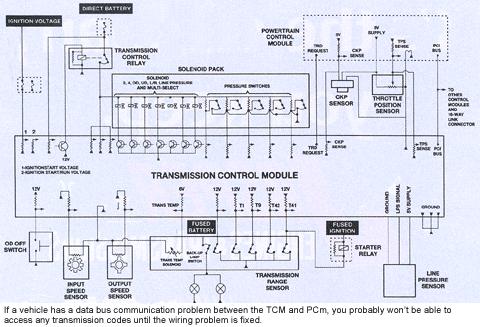

Todays electronic transmissions use sensors, solenoids and relays to regulate the operation of the clutches, gears and torque converter. On applications where these functions have not been integrated into the powertrain control module (PCM), there is a separate transmission control module (TCM) to oversee the operation of the transmission - and that is the focus of this article: how TCMs and PCMs interact.

Just like the PCM, the TCM needs accurate information to do its job properly. If the transmission computer receives bad information from the transmissions own internal sensors or bad inputs from the PCM or other engine sensors, it will have an adverse effect on how the transmission operates. It may not shift smoothly. It may shift at the wrong rpm. It may even go into a "limp-in" mode and remain frozen in second or third gear.

Essential Information

Electronic transmissions are getting smarter all the time. Most of the current generation units have fully adaptive control systems that "learn" the best shift points based on real-time sensor inputs and feedback. The transmission computer adapts the shift strategy to compensate for changes in engine performance and wear in the transmission friction elements in the clutches. By making subtle changes to the shift points and engagement, the computer tries to maintain consistent shift quality.

The transmission computer monitors what is happening inside the transmission with various speed and gear range sensors that tell it if the gears are shifting correctly and at what speeds. But to pick the shift points, it needs certain inputs from the engine and PCM. The transmission computer needs to know how fast the vehicle is traveling. This information is provided by the vehicle speed sensor. It also needs to know engine speed (rpm) and load.

On some applications, the rpm signal is hard-wired directly to the transmission computer as well as the PCM. There is a dedicated circuit between the crankshaft position sensor and TCM to supply the rpm signal. On other applications, the rpm signal goes only to the PCM and the PCM forwards it to the TCM via a data bus circuit.

Engine load can be determined from throttle position, intake vacuum and airflow. Depending on what type of fuel injection system is used (speed density or airflow), engine load inputs may come from the throttle position sensor (TPS), manifold absolute pressure sensor (MAP) and/or a vane airflow sensor (VAF) or mass airflow sensor (MAF). As with the rpm signal, the information may be shared directly with the transmission computer or it may go through the PCM and forwarded to the TCM over the data bus.

Effects of Bad Engine Sensor Inputs on the Transmission

Because the transmission needs to know engine speed and load as well as vehicle speed to pick the right shift points, a bad sensor input or loss of a signal can create real problems for the transmission computer.

The throttle position sensor signal takes the place of the throttle kickdown linkage on older mechanical automatics. So if the TPS is reading high or low, or has a dead spot, it can affect transmission kickdown shifts when accelerating, as well as normal upshifts and downshifts, too. If the TCM cannot get a good TPS signal, it may substitute a "calculated" throttle angle provided by the PCM over the data bus. Or, if this signal is not available, it may substitute a fixed value for the TPS signal. This will obviously affect the way it shifts (transmission typically hunts for shift points) but not necessarily cause it to go into a limp-in mode.

A faulty throttle position sensor will not always set a fault code. The PCM has to be smart enough to figure out when the TPS is working properly and when it is not. Its diagnostic strategies may compare the TPS signal against engine rpm, MAP signal and/or airflow to determine if the TPS signal makes sense. If the TPS signal does not correspond to other sensor inputs that can be used to measure engine load, the PCM may set a fault code. Then again, it might not. It all depends on the self-diagnostic strategy, how sensitive it is to faults and how easily the PCM can detect problems.

Transmission Limp-In Modes

Under certain conditions, which may include the loss of one or more vital inputs to the TCM, the transmission will go into some kind of limp-in or "default" mode. When a serious fault is diagnosed (such as loss of an internal speed sensor signal) or a problem occurs in the wiring circuit to any of the shift solenoids, the TCM will kill the power to the transmission control relay and deenergize all of the shift solenoids. This usually causes the transmission to freeze in 2nd or 3rd gear. The transmission will remain in limp-in mode until (1) the problem is diagnosed and repaired, or (2) power to the TCM is momentarily turned off to "reset" the computer. This may restore normal operation temporarily, but as soon as the TCM detects the fault again, it will go back into limp-in mode.

Transmission Diagnostic Trouble Codes

Like PCMs, TCMs have the ability to self-diagnose faults and set diagnostic trouble codes that can be read with a scan tool. So if the Malfunction Indicator Lamp (MIL) is on and the transmission is not operating properly, the fault may be in the transmission - or it may be in the engine. The only way to find out is to pull the code(s) to see what is going on.

It is not unusual to blame some engine driveability problems on the transmission and vice versa. A torque converter that locks up prematurely or fails to release quickly enough can cause a driveline shudder that may feel like an engine misfire or vibration. If the torque converter fails to release at all, it can cause the engine to buck and stall when coming to a stop.

Any time you encounter a problem with an electronic automatic or find a transmission code, make sure the engine is running properly and there are no engine codes that could affect the operation of the transmission. In other words, take care of any engine problems first before attempting to diagnose a transmission problem.

If a vehicle has a data bus communication problem between the TCM and PCM, you probably will not be able to access any transmission codes until the wiring problem is fixed. Possible causes include an open or short to the ground or battery in the PCI bus circuit, or an internal failure of any module or component that is attached to the bus.

The data bus is monitored any time the ignition key is on. If no messages are received from the PCM for 10 or more seconds, it tells the TCM something is wrong and it sets a data bus code.

If the transmission can find an engine speed signal from the crankshaft position sensor or PCM, the transmission can be forced into the limp-in mode. The problem should set a crank sensor circuit fault code and turn on the MIL. Possible causes include an open or short in the crank sensor circuit, a TCM connector problem, an open or short in the crank sensor ground circuit, or an internal fault in the TCM or PCM.

On OBD II applications, various transmission codes are included in the "generic" list of OBD II codes. If the transmission computer detects a problem that may affect emissions, it will send a request over the data bus to the engine computer to turn on the MIL lamp. A code will be set in the TCM and remain there until it is cleared or no fault is detected during 40 consecutive drive cycles. The MIL may go out but leave the code in memory if no fault is detected during three consecutive drive cycles.

Illustration Courtesy of ZF Friedrichshafen AG

Seven Steps for Troubleshooting An Electronic Automatic Transmision

The recommended procedure for troubleshooting an electronic automatic transmission problem involves seven steps:

- Verify the complaint. Is the transmission really shifting improperly, shuddering, slipping, etc.?

- Verify any related symptoms. Is the engine overheating, are there engine fault codes or other driveability problems?

- Analyze the symptoms and when they occur. Does the complaint only occur when hot, cold, driving at certain speeds, etc.?

- Check for any OEM technical service bulletins that might apply to the problem.

- Isolate the fault. Use the trouble codes and diagnostic charts to narrow down the possibilities. Is the problem inside or outside the transmission. Is it hydraulic, mechanical or electronic?

- Repair the fault. Replace the faulty component, replace the transmission or repair the wiring fault.

- Verify the repair. Did you fix the problem?

Adapted from an article written by Larry Carley for Underhood Service magazine

Back to Transmission Clutch And Driveline | Back to Info Main Page

Total messages: 0