Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

Automatic Transmission Repair & Replace

An automatic transmissions that is acting up may need to be repaired or replaced. Replacement is an expensive option (typically $1800 to $2500 or more!), but in many cases it is the only option unless the problem is relatively minor. Why? Because rebuilding an automatic transmission requires special training, experience and tools.

Most general repair shops and new car dealerships won't even attempt a transmission overhaul in-house. They will replace a bad transmission with one that has been professionally rebuilt by a rebuilder who specializes in transmissions. Many transmission shops do the same thing. It is much faster, easier and less trouble to install a reman transmission than to attempt the job themselves. A reman transmission from a transmission rebuilder or a factory-authorized rebuilder comes with a warranty and is usually pre-tested.

The only other replacement option is to buy a used transmission from a salvage yard. You never know what you are getting when you buy a used transmission, so it is a gamble. Some salvage yards will exchange a transmission they sold you for another if the first one turns out to be no good, but others may not.

AUTOMATIC TRANSMISSION PROBLEMS

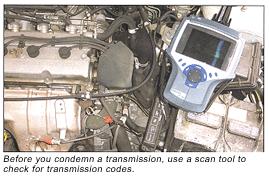

Automatic transmissions are more difficult to diagnose than manual transmissions. If the transmission is slipping, shifting oddly, making noise, won't go into a particular gear, etc., the list of possible causes runs the gamut from low transmission fluid to a faulty pump, solenoid, valve body or controller. With electronic automatics in late-model vehicles, scanning the on-board diagnostics may reveal one or more diagnostic trouble codes to shed light on what may be wrong with the transmission. But on older mechanical automatic transmissions, there are no fault codes. Diagnosis typically requires pressure tests and/or a road test.

If the vehicle has on-board diagnostics for the transmission and can be scanned for codes, what happens next depends on the code. If the code indicates an internal performance problem, the transmission probably will need to be replaced. But if a code indicates an electrical fault, you may be able to fix the problem without having to replace the transmission.

Electrical fault codes are set when the transmission controller or PCM detects an open or a short in a shift solenoid or other device. Performance codes are set when the computer sends out a command, such as a 2-3 shift, but the transmission doesn't respond properly.

With electrical codes, you can use a DVOM to test a solenoid's resistance. If the solenoid is open, shorted or out of specifications, it can be replaced. Performance codes, on the other hand, require further diagnosis and are often due to electrical faults in sensors.

ELECTRONIC AUTOMATIC TRANSMISSION DIAGNOSIS

Electronic transmissions use speed sensors to monitor shifts and what's going on inside the transmission. When things don't match up properly, a "ratio error" fault code may be set indicating that something is wrong with the way the transmission is shifting gears. The only way to isolate these kinds of faults is to follow the diagnostic charts for the particular code(s). Ratio error codes often turn out to be caused by a faulty shaft rpm sensor.

Regardless of what the code says, it's a good idea to check for any OEM technical service bulletins that might relate to the code or the complaint. Many times you'll find the fix in the TSB, which may require replacing a certain component or even reprogramming the transmission computer. These TSBs can be found at AllData.

TORQUE CONVERTER PROBLEMS

What may seem to be a transmission problem sometimes turns out to be a torque converter problem. Worn needle bearings in the torque converter may produce noise when the transmission is in gear, but the noise will go away when the transmission is shifted into neutral. Needle bearings are used inside the torque converter to separate the stator from the impeller, the stator from the turbine, and the turbine from the converter housing.

Torque converters contain a one-way clutch. If the clutch jams and locks the stator (which normally keeps the stator turning only one way), the converter can't circulate the fluid properly between the impeller and turbine. The resulting turbulence inside the unit can cause a lack of power at highway speeds and may cause the engine to overheat during cruise conditions. A locked one-way clutch will also cause the fluid to run dangerously hot, which can damage the transmission and lead to transmission failure. If the one-way clutch fails to hold its position and freewheels in both directions, the torque converter can't multiply torque normally and the vehicle will accelerate slowly (like starting out in second gear). The only cure for either condition is to replace the torque converter.

TORQUE CONVERTER STALL TEST

A "stall test" can be used on many transmissions to check its ability to hold torque and the operation of the converter one-way clutch. Some manufacturers don't recommend using a stall test because it stresses the transmission, so if you use this procedure, do not do it for more than five seconds at a time.

Before conducting a stall test, check the fluid level and condition. Chock the wheels and set the parking brake. Start the engine and place the transmission in drive while holding the brake pedal under firm pressure so the vehicle doesn't move. Then push the accelerator to the floor while holding the brakes on. Note the maximum rpm that the engine reaches. This is the stall speed. If it is lower than specifications, the torque converter one-way clutch is slipping. If the stall speed is higher than specifications, the transmission is slipping. Possible causes include a low fluid level, restricted fluid filter, a sticking pressure regulator valve, slipping clutches, bands, shaft splines or one-way clutch.

Most late-model automatics have some type of lockup torque converter to improve fuel economy. If the lockup fails to engage, there will be some slippage and fuel economy will drop. Causes here include a bad lockup solenoid, incorrect sensor input information to the transmission controller or PCM (typically a speed sensor) and hydraulic control problems. If the lockup fails to release, the engine may shudder and die when coming to a stop. Causes here include a faulty lockup solenoid, a sticking lockup valve, grounded lockup solenoid wiring or a missing lockup solenoid spacer plate screen.

Lockup shudder is another complaint that may be encountered. This refers to a vibration that is felt just before or after lockup occurs. This kind of problem can be hard to diagnose because the cause may be the torque converter, transmission or engine. Bad motor mounts, engine misfire, a bad CV joint or

U-joint, etc. can all cause vibrations that may be felt as a shudder throughout the drivetrain.

Another problem that affects the operation of the torque converter is a condition called "transmission drainback." One-way check valves normally keep the torque converter full of fluid when the engine is shut off. But if the transmission input shaft bushings are worn, it can create a path for fluid to drain out of the converter back into the transmission. The loss of fluid from the torque converter can make the transmission feel as if it is slipping on initial take-off for about five to 10 seconds.

If a torque converter fails a stall test or is leaking, it must be replaced. Many experts also recommend replacing the torque converter if an automatic transmission or transaxle has failed and is being replaced. Why? Because the torque converter acts like a garbage pit and traps a lot of the debris that results from normal wear. The debris may then contaminate and damage the new transmission. Why not just rinse out the old torque converter with solvent? The design of the wheels and large surface area inside the converter make it very difficult to clean.

By the time most transmissions need to be replaced, the friction linings inside a lockup converter are reaching the end of their service life. Reusing a lockup torque converter with worn linings is asking for trouble. And since there's no easy way to open up and clean or rebuild the internal components (doing so requires cutting open the housing on a lathe and rewelding the housing to seal it back up), replacement is your only option.

When replacing a torque converter, the replacement unit should have the same stall-speed rating as the original (unless you're installing a performance converter with a higher stall-speed rating). Too low a stall speed can lug the engine and overwork the transmission, while too high a stall speed can increase fuel consumption. When the new torque converter is installed, pour a quart or two of fluid into the unit before bolting it in place. This will protect the bearings and thrust surfaces during the initial startup until pressure from the transmission refills the unit.

AUTOMATIC TRANSMISSION REPLACEMENT TIPS

If a diagnosis reveals internal transmission problems that require replacing the transmission, here are some tips that can prevent comebacks:

- Flush out the ATF oil cooler lines to make sure they are clear and contain no debris (very important if the transmission has failed due to overheating or contains contaminated fluid).

- Recommend adding an auxiliary ATF cooler if the vehicle is used for towing, off-roading or racing. Keeping fluid temperatures within safe limits will help prolong the life of the transmission.

- Use the type of ATF specified by the vehicle manufacturer when refilling the transmission. Honda, Mercedes-Benz and others all have their own unique fluid requirements. Make sure the ATF you use meets OEM specifications.

- Read the installation instructions that come with a reman transmission. Some applications may require special care to align dowel pins, a special adjustment procedure for the throttle valve cable, etc.

- On applications with diesel engines and mechanical vacuum pumps, make sure the pump is working correctly and that all vacuum lines are correctly routed.

- On rear-wheel-drive cars and trucks, inspect the U-joints in the driveshaft. On front-wheel-drive cars and minivans, inspect the CV joints and boots. Replace any parts that are worn or damaged.

- Pay close attention to the condition of the motor and transmission mounts, especially fluid-filled hydroelastic mounts. Replace any mounts that are cracked, loose or leaking.

AUTOMATIC TRANSMISSION FLUID (ATF) SERVICE TIPS

Many transmission experts say most transmission problems can be prevented by changing the transmission fluid and filter regularly as preventive maintenance. How often depends on how the vehicle is driven. For some vehicles, this might be every 30,000 miles or two years.

The harder the transmission works, the hotter the fluid runs. The life of the fluid drops quickly once its temperature gets up above about 200 F. ATF also becomes contaminated with normal wear particles from the clutch plates, bushings and gears. The filter will trap most of this debris before it can cause problems. But many older Asian transmissions only have a plastic or metal screen that does little to protect the transmission against internal contaminants and nothing to keep the fluid clean. On these vehicles, changing the fluid is the only way to get rid of these contaminants.

Changing the fluid by dropping the transmission pan can leave up to three or four quarts of old, oxidized fluid inside the torque converter. A better way to change ATF is to use equipment that exchanges new fluid for old while the engine is running. Such equipment can usually replace up to 90 percent or more of the old fluid.

FINDING A TRANSMISSION SUPPLIER

Detlef Herrman, president of Precision European Inc., a rebuilder of BMW and Mercedes-Benz transmissions, says shops should ask the following questions when evaluating a potential transmission supplier:

- How long has the company been in business?

- Do they specialize in certain makes/models, or do they do all types of transmissions? (Herrman insists that specialists are better).

- Who runs the company, and do they still have a personal relationship with their products?

- How many times has the business changed owners over the years?

- How many different vehicle brands do they cover? (fewer is better).

- How is their inventory coverage? Do they cover the model years you service?

- How large is their core inventory? Do they need your old core before they can start the rebuilding process?

- Do they have finished transmissions in stock ready to go?

- Do they offer technical support and diagnostic help?

- Do they offer diagnostic equipment, especially for late-model electronic transmissions?

- Do they have access to the latest technical updates from manufacturers, and do they incorporate these improvements into their products?

- Can they match OEM warranties (at least 24 months)?

- What exactly does their warranty cover?

- Are they willing to show you their business facilities, either in photos or in person?

- Can they show you the type of rebuilding and test equipment they use in their facility?

- Do they provide technical data about their equipment?

- Do they use OEM-quality parts?

- What exactly is included in their rebuild procedure, and what are their criteria for replacing certain parts?

- Can they give you 10 customer references to back up their claims of quality and service?

- Do they have a sales person who can help you sell your customer on the need for a replacement transmission?

- Do they follow up after a warranty situation to make sure you were satisfied?

- Is their pricing clear and understandable?

Automatic Transmission Related Links:

AAMCO transmission shops

ATK Remanufactured Transmissions

Automatic Transmission Rebuilders Assn. (ATRA) (Search for ATRA member shops in your area)

BMW Transmission Service Information

Ford Transmission Applications

Jasper Transmissions

Transmission Digest magazine technical articles

Transmission Rebuilders Network Worldwide

Transmission & Torque Converter Application & Identification Guide

Valeo Transmission & Clutch Troubleshooting Tips

Adapted from an article written by Larry Carley for Import Car magazine

Back to Transmission Clutch And Driveline | Back to Info Main Page