Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

Troubleshoot Idle Speed Control System

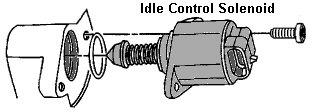

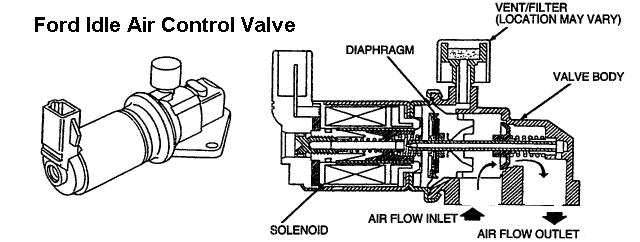

The Idle Speed Control (ISC) valve, also called an Idle Air Control (IAC) valve, is used on both throttle body and multipoint fuel injected engines to regulate idle speed. Chrysler calls theirs an Automatic Idle Speed (AIS) motor while Ford refers to theirs as an Idle Speed Control (ISC) solenoid.

The IAC valve opens a small bypass circuit that allows air to bypass the throttle. Increasing the volume of air that flows through the bypass circuit around the throttle increases idle speed. Reducing the bypass airflow decreases idle speed.

The ISC valve is controlled by the engine's computer (powertrain control module or PCM). The computer monitors idle speed by counting ignition pulses from the ignition module in the distributor or crankshaft position sensor when the throttle position sensor or throttle switch signals the computer that the throttle is closed and the engine is at idle.

When the engine's idle speed is above or below the preset range in the computer's program, the computer commands the ISC valve to either increase or decrease the bypass air flow. Additional sensor inputs from the coolant sensor, brake switch and speed sensor may also be used by the computer to regulate idle speed according to various operating conditions.

Idle speed may also be increased when the A/C compressor is engaged, the alternator is charging above a certain voltage, and/or the automatic transmission is in gear to prevent the engine from lugging down.

DIAGNOSING IDLE SPEED PROBLEMS

If you engine is idling too fast, too slow or stalling, the problem may not be the idle speed control system, but an engine vacuum leak. Check for vacuum leaks first to rule out this possibility.

A common condition is to find the idle air bypass solenoid extended all the way out (closed). This usually means the engine has an air leak and the PCM is trying to bring the idle speed back down by closing the idle air bypass circuit.

If there is an open or short in the idle air control solenoid, wiring or driver circuit, or the idle speed it out of range, it will usually set one or more fault codes and turn on the Check Engine light. If the light is on, you need to plug a scan tool into the diagnostic connector and read out the codes that set the light.

GENERAL MOTORS IDLE SPEED CONTROL

On older pre-OBD II cars, A code 11 indicates a problem in the idle air control circuit. On OBD II vehicles (1996 & newer), codes P505 to P509 indicate a fault with the idle speed control system.

The diagnostic procedure involves disconnecting ISC motor, then starting the engine to see if the idle speed increases (it should). Turn the engine off, reconnect IAC and start the engine again. This time the idle speed should return to normal. If it does, the problem is not in the IAC circuit or motor. Check for vacuum leaks or other problems that would affect idle speed.

If the idle speed does not change when the IAC is unplugged, and/or does not return to normal after reconnecting the unit, use a test light to check the idle speed control solenoid wiring circuits while the key is on. The test light should flash on and or go from bright to dim on all four circuits if the PCM and wiring are okay (this would tell you teh fault is in the ISC motor). If the test light fails to flash on one or more circuits, the fault is in the wiring or PCM.

FORD IDLE AIR BYPASS

Ford doesn't use idle air bypass to regulate idle speed on its older throttle body (CFI) applications, but uses a solenoid or vacuum diaphragm instead to open the throttle linkage. Idle air bypass is used only on multipoint injection applications. On older pre-OBD II cars, codes 12, 13, 16, 17 & 19 all indicate idle speed is out of spec (too high or too low). Codes 47 and 48 indicate a fuel mixture problem which could be caused by an air leak. On OBD II vehicles (1996 & newer), codes P505 to P509 indicate a fault with the idle speed control system.

The diagnostic procedure when any of these codes are found is to turn the engine off, unplug the ISC bypass air solenoid connector, then restart the engine to see if the idle rpm drops (it should if the ISC solenoid is working). No change would indicate a problem in the motor or wiring.

The ISC solenoid can be checked by measuring its resistance. With the positive lead of a digital volt/ohm meter on the VPWR pin and the negative lead on the ISC pin, measure the resistance of the solenoid. On many applications, the spec calls for 7.0 to 13.0 ohms. If it is out of specs, the ISC solenoid is bad. Also check for shorts between both ISC solenoid terminals and the case.

If the ISC checks out okay, check for battery voltage between the ISC connector terminals while the key is on. Voltage should also vary when the engine is running. No voltage indicates a wiring or computer problem.

CHRYSLER IDLE SPEED CONTROL

On pre-OBD II Chryslers, a Code 25 means there is a problem in the AIS motor driver circuit. On OBD II vehicles (1996 & newer), codes P505 to P509 indicate a fault with the idle speed control system.

The AIS driver circuit can be checked with a bi-directional scan tool using commands to increase idle speed. No change in commanded idle speed would tell you there is a problem in the driver circuit, the wiring or the solenoid. You can remove the AIS from the throttle body to see if the valve pintle is moving in and out, or simply listen for the motor to buzz.

In the engine running test mode #70, which checks the throttle body minimum air flow, depressing and holding the proper button on a hand held scan tool should close the AIS bypass circuit. At the same time, ignition timing and fuel mixture are fixed. Idle speed should increase to about 1300 to 1500 rpm. If it doesn't match the specs, the minimum air flow through the throttle body is incorrect.

INSTALLING A NEW IDLE SPEED CONTROL SOLENOID

When installing a new GM IAC or Chrysler AIS solenoid, the pintle must not extend more than a certain distance from the housing. The specs vary so check the manual or look up the specs on the OEM service information website or on Alldata. Chrysler says one inch (26 mm) is the limit, while some GM allows up to 28 mm on some units and 32 mm on others. If the pintle is overextended, it can be retracted by either pushing it in (GM) or by connecting it to its wiring harness and using actuator test 03 to move it in (Chrysler).

Back to Driveability Diagnostics Emissions | Back to Info Main Page